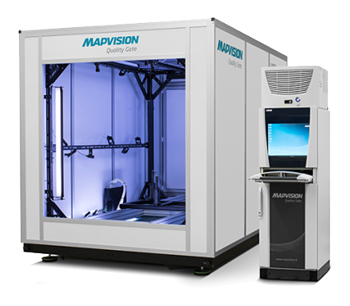

Mapvision Quality Gate

The Mitutoyo Corporation joined forces with Mapvision Ltd, the in-line inspection specialist headquartered in Helsinki/Finland.

The strategic partnership with a global sales cooperation aims at enhancing added value of in-line inspection and product line-up within MITUTOYO reinforce position as a leader in high-technology.

Mapvision Quality Gate is the fastest in-line inspection system for welded car body and chassis components available on the market today. It can inspect complex welded assemblies like cross car beams, subframes and axles within the line cycle time, typically hundreds of 3D features (x,y,z) in less than 30 seconds.

Mapvision Quality Gate is the fastest in-line inspection system for welded car body and chassis components available on the market today. It can inspect complex welded assemblies like cross car beams, subframes and axles within the line cycle time, typically hundreds of 3D features (x,y,z) in less than 30 seconds.

Mapvision multi-camera technology raises in-line inspection to a new level. Our solution is entirely software-based, so it doesn’t suffer from the limitations and problems that come from using robots or mechanical probes for measurement. You get a unique result that no one else can provide:

-100% x 100% inspection

-CMM comparable measurement data within line cycle time

-Superior reliability and more uptime in real factory conditions

This means you don't deliver any bad parts, which prevents the associated quality costs and loss of reputation. Your internal efficiency increases, as you can adjust your line to nominal, using 100% inspection data that is available immediately.