- Nederlands, Belgique / België

- Česky, Česká republika

- Deutsch, Deutschland

- Español, España

- Português, Portugal

- English, Europe

- Français, France

- Italiano, Italia

- Magyar, Magyarország

- Nederlands, Nederland

- Deutsch, Österreich

- Polski, Polska

- Română, România

- Suisse / Schweiz / Svizzera

- Svenska, Sverige

- Suomeksi, Suomi

- Türkçe, Türkiye

- English, United Kingdom

- Slovenská, Slovak

-

Worldwide

- Toate Produse evidențiate

- QuantuMike

- LEGEX Takumi

- Seria STRATO-Active

- Measurlink 10

- TAGLENS

- MCOSMOS 5

- Crysta Apex V

- Formtracer Avant

- MiSTAR 555

- Șublere

- Transmisii de date bluetooth

- QuickVision Pro

- Toate Produse după domeniul industrial

- Industria Aeronautică

- Medicală

- Auto

- Energie

- Prelucrări Mecanice

- Electronică

- Producători de echipamente originale (OEM)

- Studii de caz

- Toate Instrumente mici

- Șublere

- Micrometre & Capete micrometrice

- Instrumente de măsurare în interior

- Instrumente de măsurare a adâncimii

- Coloane de măsurat

- Comparatoare & Pupitasturi

- Instrumente auxiliare și diverse

- Instrumente de calibrare

- Cale plan paralele

- Toate CMM - Mașini de măsurat în coordonate 3D

- Mașini de măsurat in coordonate mici și mijlocii

- Mașini de măsurat în coordonate pe Linia de producție & Atelier

- Mașini de măsurat în coordonate mari

- Mese rotative - CMM

- Senzori

- Palpatori

- Sisteme de Fixare & Prindere

- Împrejmuiri - CMM

- CMM Software

- Toate Mașini de măsurat tip Vision

- Sisteme Vision Manuale 2D

- Sisteme Vision Manuale 3D

- Sisteme Vision 3D CNC

- Sisteme Vision 3D CNC Multi-sensor

- Sisteme Vision MiSCAN

- Sisteme Vision microgeometrie 3D CNC

- Software sisteme Vision

- Accesorii sisteme Vision

- Sisteme de prindere Vision

- Palpatori Sisteme Vision System

- Toate Optice

- Lupe

- Proiectoare de pofile

- Microscoape de măsurare

- Unități Microscop

- Obiective

- M2 pentru Microscoape de măsurare și Proiectoare de profile

- TAGLENS

- Dispozitive de măsurare optică

- Toate Duritate

- Testere portabile de duritate

- Testere de duritate combinate

- Testere de duritate Vickers

- Testere de duritate Vickers Automatic

- Testere de duritate Micro-Vickers

- Hardness Testing Software

- Materiale de referință și indentatori

- Toate Senzori

- Traductoare liniare

- Indicatori cu forță redusă

- Contoare și unități de afișare

- Micrometre cu fantă laser

- Surface Measure

- Software pentru managementul de senzori

- Micrometre & Capete micrometrice

- Micrometre Digitale & Mecanice

- Accessorii micrometre

- Capete Micrometrice

- Capete Micrometrice accesorii

- Instrumente de măsurare în interior

- Micrometre de interior

- Micrometre de alezaj

- Micrometre de interior & de alezaj accesorii

- Instrumente de măsurare a adâncimii

- Micrometre de adâncime

- Șublere de adâncime & comparatoare de adâncime

- Accessorii șublere de adâncime

- Coloane de măsurat

- Coloane de măsurat cu procesare date

- Coloane de măsurat

- Accesorii coloane de măsurat

- Comparatoare & Pupitasturi

- Comparatoare digitale

- Accesorii comparatoare

- Pupitasturi

- Comparatoare cu cadran

- Accesorii comparatoare cu cadran și pupitasturi

- Grosimetre & Dinamometru cu cadran

- Instrumente auxiliare și diverse

- Suporturi Comparatoare

- Menghine de precizie

- Mese și standuri de Granite

- Raportoare si Echere de 90⁰

- Lere, liniare drepte și muchii active

- Instrumente de calibrare

- Bloc etalon de înălțime - Height Master

- Bloc etalon - Check Masters

- Scule de Calibrare

- Cale plan paralele

- Seturi de cale plan paralele de oțel

- Cale plan paralele de oțel

- Seturi de cale plan paralele de ceramică

- Cale plan paralele de ceramică

- Cale plan paralele speciale

- Accesorii cale plan paralele

- Accesorii petnru cale plan paralel patrate

- Mașini de măsurat in coordonate mici și mijlocii

- Seria CRYSTA-Apex V - 500, 700, & 900

- Seria CRYSTA-Apex V - 1200, 1600 & 2000

- Seria CRYSTA-Apex EX Series cu cap REVO

- Seria STRATO-Active

- Seria STRATO-Apex - 500, 700, & 900

- Seria STRATO-Apex - 1600

- Seria LEGEX

- Mașini de măsurat în coordonate pe Linia de producție & Atelier

- MACH Ko-ga-me

- MACH 3A 653

- MACH V 9106

- MiSTAR 555

- Palpatori

- Kituri de palpatori

- Palpatori drepți

- Palpatori acoperite cu diamant

- Palpatori din diamant

- Master Ball - Bilă etalon

- Palpatori pentru mașini de prelucrat

- Palpatori tip stea

- Palpatori pentru palpatori tip stea

- Palpatori pentru suporturi de prindere

- Palpatori cilindrici

- Palpatori tip disc

- Palpatori cu vârf

- Extensii

- Suporturi - Holdere

- Adaptori

- Articulații

- Șuruburi pentru cuburi

- Scule

- StyliCleaner

- Sisteme de Fixare & Prindere

- Kit-uri de prindere - CMM

- Kit-uri Sisteme de recepție pentru paleți Eco-fix

- Software FixtureBuilder

- Seturi de extensie Eco-fix și Eco-fixplus

- Componente Eco-fix și Eco-fixplus

- Eco-fix șuruburi și scule

- Sisteme Vision 3D CNC

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

- Sisteme de prindere Vision

- Kituri de prindere pentru măsurători optice

- Componente Opti-fix

- Opti-fix Șuruburi și scule

- Palpatori Sisteme Vision System

- Palpatori drepți

- Extensii

- Palpatori tip stea

- Suporți palpatori

- Palpatori pentru configurarea palpator tip stea

- Palpatori pentru suport de prindere

- Adaptori

- Articulații

- Palpatori cilindrici

- Palpatori tip disc

- Palpatori cu vârf

- Șuruburi pentru cuburi

- Scule

- Kituri de palpatori

- Proiectoare de pofile

- Seria PJ

- Seria PV

- Seria PH

- Unitate de procesare date

- Accesorii

- Rigle gradate de precizie

- Microscoape de măsurare

- Seria TM Gen. B

- Seria MF Gen. D

- Seria MF-U Gen. D

- Surse de iluminare

- Unitate Vision

- QSPAK-VUE Software

- Camere pentru Microscoape

- Obiective

- Obiective seria ML

- Obiective de observare în câmp luminos

- Obiective de observare în câmp luminos/câmp întunecat

- Obiective NIR

- Obiective NIR LCD

- Obiective NUV

- Obiective NUV LCD

- Obiective UV

- Obiective UV LCD

- Dispozitive de măsurare optică

- Optical Measurement Fixturing Kits

- Opti-fix Components

- Opti-fix Screws and Tools

- Rugozitate

- Surftest SJ-210

- Surftest SJ-220

- Surftest SJ-310

- Surftest SJ-410

- Surftest SJ-500

- Surftest SV-2100

- Surftest SJ-500P

- Surftest SV-2100P

- Formtracer Avant FTA-S3000

- Surftest Extreme SV-3000CNC

- Surftest Extreme SV-M3000CNC

- Rugozitate & Contur

- Seria Formtracer Avant FTA-D3000 / FTA-D4000

- Formtracer CS-3300

- Formtracer Extreme SV-C4500CNC

- Formtracer Extreme SV-C4500CNC tip HYBRID 1

- Formtracer Extreme CS-5000CNC și CS-H5000CNC

- Testere portabile de duritate

- Tester al durității cu impact HARDMATIC HH-411

- Durometre digitale și analogice HARDMATIC HH-300

- Testere de duritate combinate

- Rockwell HR-200/300/400

- Rockwell, Rockwell Superficial, Brinell Hardness Tester HR-530 și HR-600

- Tester de duritate Rockwell Automatic HR-600

- Testere de duritate Vickers Automatic

- Sisteme automate de testare a durității Micro-Vickers

- Sisteme automate de testare a durității Vickers

- Materiale de referință și indentatori

- Etaloane de duritate

- Indentatoare de duritate și bile de schimb

- Traductoare liniare

- Traductor liniar ABSOLUTE Digimatic Seria LGS

- Unitatea de aer comprimat

- Traductoare liniare seria LG100

- Traductoare liniare seria LG200

- Traductoare Laser Hologauge

- Contoare și unități de afișare

- Contor EJ și interfețe pentru traductoare liniare

- Contor EC pentru traductoare liniare

- Contor EG pentru traductoare liniare

- Contor EH Counter pentru traductoare liniare

- Contor EV Counter pentru traductoare liniare

- Unitate de afișare pentru contor EV

- Micrometre cu fantă laser

- Unitate de măsurare Micrometre cu fantă laser

- Unitatea de control Micrometre cu fantă laser

- Interfețe pentru micrometre cu fantă laser

- Accesorii opționale Micrometre cu fantă laser

- Scale liniare DRO și contoare

- Scale liniare DRO AT103

- Scale liniare DRO AT103 - de precizie

- Scale liniare DRO AT113

- Scale liniare DRO AT113 - de precizie

- Scale liniare DRO ABS AT715

- Contor Universal DRO KA-200

- Scale liniare NC

- Scale Liniare NC ST36

- Scale Liniare NC ST46-EZA

- Scale Liniare NC ABS ST700

- Scale Liniare NC ABS ST1300

- Scale Liniare NC AT211

- Scale Liniare NC ABS AT1100

- Scale Liniare NC ABS AT1300

- Unități scale liniare

- Scală Horizontal ABSOLUTE cu protecție IP66

- Scală Horizontal ABSOLUTE Standard

- Scală Horizontal ABSOLUTE Scale Measurement cu comutarea de direcție

- Scală Horizontal ABSOLUTE cu funcția diametru

- Scală liniară Vertical ABSOLUTE Standard

- Scală liniară Vertical ABSOLUTE cu comutare direcție de măsurare

- Scală liniară Vertical ABSOLUTE cu funcția diametru

- Cabluri de transmitere date

- USB Input Tool Direct (Cablu Digimatic-USB)

- Cabluri de date Digimatic

- Extensii cabluri Digimatic

- Communicații fără fir - Wireless

- Sisteme de comunicații fără fir Wireless U-WAVE

- U-WAVE Bluetooth

- Cabluri de date U-WAVE-T și unități de contact

Aeronautică

Aeronautică

Aplicațiile aeronautice complexe necesită un control al calității rapid și extrem de precis pentru a asigura ansambluri precise. Vezi cum face Mitutoyo ca acest lucru să se întâmple

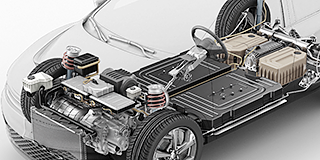

Auto

Auto

Industria auto continuă să inoveze, iar Mitutoyo oferă capabilități avansate de inspecție și scanare pentru a ajuta producătorii să realizeze o producție continuă

Energie

Energie

Soluțiile de măsurare și analiză de la Mitutoyo sunt concepute pentru a ajuta furnizorii de energie să îmbunătățească fiabilitatea și să mărească durata de funcționare a echipamentului.

Medicală

Medicală

Pentru a proteja sănătatea pacientului, aplicațiile medicale necesită o precizie excepțională. Vedeți cum soluțiile testate de la Mitutoyo vă pot ajuta să obțineți acest lucru.

Prelucrări mecanice

Prelucrări mecanice

Asigurați o repetabilitate ridicată și un control riguros al calității cu soluții de măsurare a formei, mașini de măsurare în coordonate și instrumente de măsurare de precizie de la Mitutoyo.

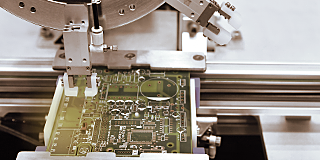

Electronică

Electronică

Soluțiile de măsurare non contact și tip Vision de la Mitutoyo aduc precizie microscopică componentelor electronice mai mici și mai dense

Producătorii de echipmente originale (OEM)

Producătorii de echipmente originale (OEM)

Mitutoyo OEM poate aborda expertiza sau resursele lipsă furnizându-vă echipamentele noastre renumite de metrologie care se integrează perfect în produsele dumneavoastră.

Studii de caz

Studii de caz

Pentru o privire de ansamblu asupra capabilităților lui Mitutoyo, nu exista un loc mai bun în care să căutați decât minunata noastră colecție de studii de caz.

Mitutoyo Japan Desk

Mitutoyo Japan Desk

Prima oprire pentru companiile japoneze care operează în Europa

Produse personalizate

Produse personalizate

Produse personalizate pentru aplicații unice

Integrarea producției automatizate

Integrarea producției automatizate

Transformă-ți fabrica într-o fabrică inteligentă cu ajutorul Mitutoyo

Integratorii Mitutoyo

Integratorii Mitutoyo

Integrarea dispozitivelor dumneavoastră de măsurare în procesele existente devine ușoară

Reparații & Piese de schimb

Reparații & Piese de schimb

Piese de schimb și reparații pentru dispozitive Mitutoyo

Etalonare

Etalonare

Obțineți dispozitivele de măsurare calibrate de la un laborator în care aveți încredere

Servicii pe teren

Servicii pe teren

Service la fața locului pentru aparatele dumneavoastră preferate de măsurare și testare

Servicii de Măsurare

Servicii de Măsurare

Măsurați piesele și piesele dvs. de oriunde în Europa

Demonstrații Produse

Demonstrații Produse

Online sau offline, obțineți o demonstrație a produsului astăzi

Suport IT

Suport IT

Instalare și integrare perfectă și fără probleme în infrastructura dvs. IT.

Soluții pentru Fabrica Inteligentă

Soluții pentru Fabrica Inteligentă

Transformă-ți fabrica într-o fabrică inteligentă cu ajutorul Mitutoyo

Pachetul educațional

Pachetul educațional

Perfect pentru atelier sau sala de clasă, nu există un ajutor mai mare decât afișele sau materialul educațional de la Mitutoyo

E-Learning

E-Learning

Pentru cei interesați de metrologie, Mitutoyo oferă cursuri de e-Learning pentru a ajuta la pregătirea studenților, personalului sau chiar pasionaților

Online Material

Online Material

If you're looking for a quick way to learn more about measurement, check out our many instructional videos.

Descoperiți Mitutoyo

Descoperiți Mitutoyo

Cea mai mare companie de metrologie din lume

Cariere

Cariere

Află mai multe despre cum te simți să lucrezi la Mitutoyo și următorii pași pentru a-ți începe cariera aici

Merchandising

Merchandising

The popular destination for high-quality Mitutoyo apparel and more!

Presă

Presă

Consultați cele mai recente știri, actualizări și resurse

Evenimente

Evenimente

Rămâneți la curent cu evenimentele noastre din toată Europa și vedeți aici și noutățile de la Mitutoyo

Promoții speciale

Promoții speciale

Verifică și vezi care dintre produsele tale preferate au reducere luna aceasta

Software

Software

Descărcați software-ul și actualizările noastre simplu și ușor

Declarații de conformitate

Declarații de conformitate

Aici puteți descărca versiunile complete pentru UE și Marea Britanie

Postere Gratuite

Postere Gratuite

Descărcați gratuit postere oficiale Mitutoyo aici

Materiale de comunicare a brandului Mitutoyo

Materiale de comunicare a brandului Mitutoyo

Resurse pentru personalul Mitutoyo și furnizorii externi

-

Produse

- Înapoi Produse

- Produse

- Produse evidențiate

- Produse după domeniul industrial

-

Instrumente mici

- Înapoi Instrumente mici Toate Instrumente mici

- Șublere

-

Micrometre & Capete micrometrice

- Înapoi Micrometre & Capete micrometrice Micrometre & Capete micrometrice

- Micrometre Digitale & Mecanice

- Accessorii micrometre

- Capete Micrometrice

- Capete Micrometrice accesorii

-

Instrumente de măsurare în interior

- Înapoi Instrumente de măsurare în interior Instrumente de măsurare în interior

- Micrometre de interior

- Micrometre de alezaj

- Micrometre de interior & de alezaj accesorii

-

Instrumente de măsurare a adâncimii

- Înapoi Instrumente de măsurare a adâncimii Instrumente de măsurare a adâncimii

- Micrometre de adâncime

- Șublere de adâncime & comparatoare de adâncime

- Accessorii șublere de adâncime

- Coloane de măsurat

- Comparatoare & Pupitasturi

- Instrumente auxiliare și diverse

-

Instrumente de calibrare

- Înapoi Instrumente de calibrare Instrumente de calibrare

- Bloc etalon de înălțime - Height Master

- Bloc etalon - Check Masters

- Scule de Calibrare

- Cale plan paralele

-

CMM - Mașini de măsurat în coordonate 3D

- Înapoi CMM - Mașini de măsurat în coordonate 3D Toate CMM - Mașini de măsurat în coordonate 3D

-

Mașini de măsurat in coordonate mici și mijlocii

- Înapoi Mașini de măsurat in coordonate mici și mijlocii Mașini de măsurat in coordonate mici și mijlocii

- Seria CRYSTA-Apex V - 500, 700, & 900

- Seria CRYSTA-Apex V - 1200, 1600 & 2000

- Seria CRYSTA-Apex EX Series cu cap REVO

- Seria STRATO-Active

- Seria STRATO-Apex - 500, 700, & 900

- Seria STRATO-Apex - 1600

- Seria LEGEX

-

Mașini de măsurat în coordonate pe Linia de producție & Atelier

- Înapoi Mașini de măsurat în coordonate pe Linia de producție & Atelier Mașini de măsurat în coordonate pe Linia de producție & Atelier

- MACH Ko-ga-me

- MACH 3A 653

- MACH V 9106

- MiSTAR 555

-

Mașini de măsurat în coordonate mari

- Înapoi Mașini de măsurat în coordonate mari Mașini de măsurat în coordonate mari

- STRATO Apex G

- Seria - CARB

-

Mese rotative - CMM

- Înapoi Mese rotative - CMM Mese rotative - CMM

- Masa rotativă MRT240

- Masa rotativă MRT320

- Senzori

-

Palpatori

- Înapoi Palpatori Palpatori

- Kituri de palpatori

- Palpatori drepți

- Palpatori acoperite cu diamant

- Palpatori din diamant

- Master Ball - Bilă etalon

- Palpatori pentru mașini de prelucrat

- Palpatori tip stea

- Palpatori pentru palpatori tip stea

- Palpatori pentru suporturi de prindere

- Palpatori cilindrici

- Palpatori tip disc

- Palpatori cu vârf

- Extensii

- Suporturi - Holdere

- Adaptori

- Articulații

- Șuruburi pentru cuburi

- Scule

- StyliCleaner

- Sisteme de Fixare & Prindere

-

Împrejmuiri - CMM

- Înapoi Împrejmuiri - CMM Împrejmuiri - CMM

- Împrejmuiri - CMM

-

CMM Software

- Înapoi CMM Software CMM Software

- MiCAT Planner

- MCOSMOS

- MAFIS Express

- MSURF

-

Mașini de măsurat tip Vision

- Înapoi Mașini de măsurat tip Vision Toate Mașini de măsurat tip Vision

-

Sisteme Vision Manuale 2D

- Înapoi Sisteme Vision Manuale 2D Sisteme Vision Manuale 2D

- Quick Image

- Quick Image Software

-

Sisteme Vision Manuale 3D

- Înapoi Sisteme Vision Manuale 3D Sisteme Vision Manuale 3D

- Manual Quick Scope

- Quick Scope Software

-

Sisteme Vision 3D CNC

- Înapoi Sisteme Vision 3D CNC Sisteme Vision 3D CNC

- Quick Vision ACTIVE

- Quick Vision APEX / HYPER

- Quick Vision ACCEL

- Quick Vision ULTRA

-

Sisteme Vision 3D CNC Multi-sensor

- Înapoi Sisteme Vision 3D CNC Multi-sensor Sisteme Vision 3D CNC Multi-sensor

- Quick Vision Hybrid

- Quick Vision WLI

-

Sisteme Vision MiSCAN

- Înapoi Sisteme Vision MiSCAN Sisteme Vision MiSCAN

- MiSCAN APEX 404

- MiSCAN HYPER 302

- MiSCAN HYPER 404

-

Sisteme Vision microgeometrie 3D CNC

- Înapoi Sisteme Vision microgeometrie 3D CNC Sisteme Vision microgeometrie 3D CNC

- Sistem Vision UMAP

- UMAP Software

-

Software sisteme Vision

- Înapoi Software sisteme Vision Software sisteme Vision

- QVPAK

- QSPAK

- QIPAK

- Accesorii sisteme Vision

-

Sisteme de prindere Vision

- Înapoi Sisteme de prindere Vision Sisteme de prindere Vision

- Kituri de prindere pentru măsurători optice

- Componente Opti-fix

- Opti-fix Șuruburi și scule

-

Palpatori Sisteme Vision System

- Înapoi Palpatori Sisteme Vision System Palpatori Sisteme Vision System

- Palpatori drepți

- Extensii

- Palpatori tip stea

- Suporți palpatori

- Palpatori pentru configurarea palpator tip stea

- Palpatori pentru suport de prindere

- Adaptori

- Articulații

- Palpatori cilindrici

- Palpatori tip disc

- Palpatori cu vârf

- Șuruburi pentru cuburi

- Scule

- Kituri de palpatori

-

Optice

- Înapoi Optice Toate Optice

- Lupe

-

Proiectoare de pofile

- Înapoi Proiectoare de pofile Proiectoare de pofile

- Seria PJ

- Seria PV

- Seria PH

- Unitate de procesare date

- Accesorii

- Rigle gradate de precizie

- Microscoape de măsurare

-

Unități Microscop

- Înapoi Unități Microscop Unități Microscop

- Unități Microscop seria FS70

- Unitate Video Microscop Seria VMU

- Obiective

- M2 pentru Microscoape de măsurare și Proiectoare de profile

- TAGLENS

-

Dispozitive de măsurare optică

- Înapoi Dispozitive de măsurare optică Dispozitive de măsurare optică

- Optical Measurement Fixturing Kits

- Opti-fix Components

- Opti-fix Screws and Tools

-

Formă

- Înapoi Formă Toate Formă

- Rugozitate

- Contur

- Rugozitate & Contur

-

Formă

- Înapoi Formă Formă

- Roundtest

- Roundtracer

-

Software FMI

- Înapoi Software FMI Software FMI

- Formtracepak

- Roundpak

-

Duritate

- Înapoi Duritate Toate Duritate

-

Testere portabile de duritate

- Înapoi Testere portabile de duritate Testere portabile de duritate

- Tester al durității cu impact HARDMATIC HH-411

- Durometre digitale și analogice HARDMATIC HH-300

- Testere de duritate combinate

-

Testere de duritate Vickers

- Înapoi Testere de duritate Vickers Testere de duritate Vickers

- Testere de duritate Vickers HV-110/120

-

Testere de duritate Vickers Automatic

- Înapoi Testere de duritate Vickers Automatic Testere de duritate Vickers Automatic

- Sisteme automate de testare a durității Micro-Vickers

- Sisteme automate de testare a durității Vickers

-

Testere de duritate Micro-Vickers

- Înapoi Testere de duritate Micro-Vickers Testere de duritate Micro-Vickers

- Testere de duritate Micro-Vickers HM-210/220

-

Hardness Testing Software

- Înapoi Hardness Testing Software Hardness Testing Software

- AVPAK

-

Materiale de referință și indentatori

- Înapoi Materiale de referință și indentatori Materiale de referință și indentatori

- Etaloane de duritate

- Indentatoare de duritate și bile de schimb

-

Senzori

- Înapoi Senzori Toate Senzori

- Traductoare liniare

-

Indicatori cu forță redusă

- Înapoi Indicatori cu forță redusă Indicatori cu forță redusă

- LITEMATIC VL-50 comparator motorizat cu forță redusă, de precizie

-

Contoare și unități de afișare

- Înapoi Contoare și unități de afișare Contoare și unități de afișare

- Contor EJ și interfețe pentru traductoare liniare

- Contor EC pentru traductoare liniare

- Contor EG pentru traductoare liniare

- Contor EH Counter pentru traductoare liniare

- Contor EV Counter pentru traductoare liniare

- Unitate de afișare pentru contor EV

- Micrometre cu fantă laser

-

Surface Measure

- Înapoi Surface Measure Surface Measure

- Surface Measure 1008S

- Surface Measure 0303S

- Accesorii

- Software pentru managementul de senzori

-

Scale liniare Digitale

- Înapoi Scale liniare Digitale Toate Scale liniare Digitale

- Scale liniare DRO și contoare

- Scale liniare NC

-

Unități scale liniare

- Înapoi Unități scale liniare Unități scale liniare

- Scală Horizontal ABSOLUTE cu protecție IP66

- Scală Horizontal ABSOLUTE Standard

- Scală Horizontal ABSOLUTE Scale Measurement cu comutarea de direcție

- Scală Horizontal ABSOLUTE cu funcția diametru

- Scală liniară Vertical ABSOLUTE Standard

- Scală liniară Vertical ABSOLUTE cu comutare direcție de măsurare

- Scală liniară Vertical ABSOLUTE cu funcția diametru

-

Gestiunea datelor

- Înapoi Gestiunea datelor Toate Gestiunea datelor

-

Software managementul datelor

- Înapoi Software managementul datelor Software managementul datelor

- MeasurLink 10

- USB-ITPAK

-

Procesoare digitale Mini

- Înapoi Procesoare digitale Mini Procesoare digitale Mini

- Procesor Digimatic Mini DP-1VA LOGGER

-

Cabluri de transmitere date

- Înapoi Cabluri de transmitere date Cabluri de transmitere date

- USB Input Tool Direct (Cablu Digimatic-USB)

- Cabluri de date Digimatic

- Extensii cabluri Digimatic

-

Communicații fără fir - Wireless

- Înapoi Communicații fără fir - Wireless Communicații fără fir - Wireless

- Sisteme de comunicații fără fir Wireless U-WAVE

- U-WAVE Bluetooth

- Cabluri de date U-WAVE-T și unități de contact

- Interfețe

-

Timerbox, Casetă Digimatic comutare

- Înapoi Timerbox, Casetă Digimatic comutare Timerbox, Casetă Digimatic comutare

- Digimatic Timerbox

- Casetă Digimatic comutare

-

Software

- Înapoi Software Toate Software

-

Software - mașini de măsurat in coordonate 3D

- Înapoi Software - mașini de măsurat in coordonate 3D Software - mașini de măsurat in coordonate 3D

- MiCAT Planner

- MCOSMOS

- MAFIS-Express

- MSURF

-

Software sisteme Vision

- Înapoi Software sisteme Vision Software sisteme Vision

- QVPAK

- QSPAK

- QIPAK

-

Software FMI

- Înapoi Software FMI Software FMI

- Formtracepak

- Roundpak

- Software evaluare Duritate

- Software senzori

-

Software Gestiunea Datelor

- Înapoi Software Gestiunea Datelor Software Gestiunea Datelor

- Measurlink 10

- USB-ITPAK

- Sisteme de tomografie computerizată

- Industrie

-

Servicii

- Înapoi Servicii

- Servicii

- Mitutoyo Japan Desk

- Produse personalizate

- Integrarea producției automatizate

- Integratorii Mitutoyo

- Reparații & Piese de schimb

- Etalonare

- Servicii pe teren

- Servicii de Măsurare

- Demonstrații Produse

- Suport IT

-

Soluții pentru Fabrica Inteligentă

- Înapoi Soluții pentru Fabrica Inteligentă

- Soluții pentru Fabrica Inteligentă

-

Cursuri de metrologie și despre produse

- Înapoi Cursuri de metrologie și despre produse

- Cursuri de metrologie și despre produse

- Educație

- Despre noi

-

Noutăți

- Înapoi Noutăți

- Noutăți

- Presă

-

Evenimente

- Înapoi Evenimente

- Evenimente

-

Promoții speciale

- Înapoi Promoții speciale

- Promoții speciale

- Promoție MiSTAR - PH 20 la pachet

- Descărcări

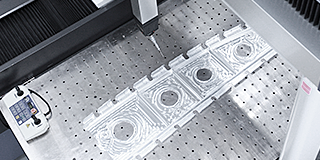

Leeds, West Yorkshire based FTL Technology is one the UK’s leading suppliers of precision engineered seal solutions. In addition to offering a broad range of consultancy, design and seal manufacturing services, the company also has access to a wide range of high quality products from many of the world’s leading seal manufacturing companies.

FTL Technology give Mitutoyo the 'seal' of approval

Having established an excellent reputation over the past 40 years, FTL Technology has attracted customers from many of the world’s most demanding of industries. The challenges faced by the food and pharmaceutical sectors can be particularly onerous. FTL Technology’s in-depth expertise within these important sectors ensures the delivery of sealing products and services that meet all of the relevant food and pharmaceutical certification requirements. Illustrating the varied problems faced by the company’s diverse customer base, seals and components used within the oil and gas industry face exposure to extreme temperatures, high pressures and intense chemical aggression. FTL Technology oil and gas sealing solutions safeguard operator safety and ensuring equipment reliability throughout this industry.

Given the countless demanding applications FTL Technology’s products are used for, extremely high standards of quality and precision permeate all of the company’s manufacturing and inspection activities. In accordance with FTL Technology’s policy of continuous improvement and to help guarantee the continued quality of the company’s sealing products, FTL Technology Quality Manager, Joanne Kite recently investigated the available high accuracy optical measuring systems that would enhance the company’s important inspection functions. After considering several options, an advanced Quick Image 2D Vision Measuring System was purchased from Mitutoyo UK.

Joanne Kite explained. “FTL Technology’s core strengths are problem solving and helping our customers to optimise their operation processes by the provision of premium quality custom sealing solutions. Having considered other optical systems, we recently further increased our precision capabilities by purchasing a non-contact vision measuring system from Mitutoyo UK. Now installed and fully operational, our Mitutoyo Quick Image machine is used for a range of precise measurement routines, such as 1starticle inspections and for checking a percentage of products during a production run.

“In addition to carrying out non-destructive vision inspecting routines on seals in their finished states, as many of our products consist of multiple elements assembled into a single seal with difficult to access features, we also slice though some of our seals. This enables the Quick Image machine to accurately inspect the cross-sections of seals. As the Quick Image system has excellent magnification capabilities, we also use the machine to greatly enlarge the images of components, allowing us to undertake detailed visual investigations. By viewing blown-up images on the machine’s screen we are able to ensure that even the most microscopic of imperfections can be picked-up.

Given that many companies require traceable documentation, we are now able to print both clear product images and detailed inspection reports direct from our Mitutoyo Quick Image 2D Vision Measuring System and supply them to our customers. As conventional measurement techniques, such as the use of calipers, micrometers and CMMs with touch probes would distort some of the more deformable materials that are used in our seal products, our Mitutoyo Quick Image machine has proven to be an ideal quick acting and accurate non-contact measuring system.”

Mitutoyo Vision Measuring Systems are available in a wide range of sizes and accuracy classes to cover practically all precision 2D and 2½D measuring applications, with every system representing an excellent investment in terms of productivity, versatility, quality of construction, training and service support.

In addition to high-performance vision capabilities, contact probes are available on some systems to further extend their range of measurement applications. Also, dedicated analysis software is offered that rapidly interprets measurement results and enables inspection functions to keep pace with today’s fast-paced production.

The latest version of Mitutoyo’s versatile Quick Image series 2D vision measuring system, as purchased by FTL Technology, is a high-quality system that is designed, to provide efficient, measurement in the inspection room or in the laboratory. Available with 0.2× or 0.5× magnification, the cost-effective Quick Image 2D Vision Measuring System is deal for applications that require distortion-free imaging with accurate non-contact measurement capabilities.

A telecentric lens provides uses with a field of view and depth of focus that makes the measurement of workpieces with multiple step heights both fast and precise, whilst the system’s convenient one-click measurement function allows measurement and tolerance judgment with the click of a mouse. This feature enables the automatic detection of a workpiece position and inclination and also aids the efficient measurement of multiple workpieces that share the same shape. A maximum of 1,000 parts able to be measured in a single measuring routine.

The use of high luminance, with built-in LED lighting and a premium quality 3-megapixel colour camera, enable observations and accurate measurements using high-resolution images. The Quick Image series 2D’s measured results are displayed in real time directly on the system’s video image screen, allowing tolerance limits to be clearly seen at a glance.

Additional features include the ability to switch between large-focal-depth mode (normal) and high-resolution mode; wide field, rapid batch and high-accuracy measurement; user defined overlay templates; and a large line-up of X and Y stage sizes. The use of simple, extremely logical controls ensures that new users are quickly able to master the use of the Quick Image series 2D vision measuring system and to achieve precise results. To further aid adoption by users new to the system an ‘easy mode’ is also included.